Test Rig for Organic VApors (TROVA)

To investigate experimentally the non-ideal compressible-fluid flows of organic compounds in typical operating conditions for ORC applications, the Test Rig for Organic Vapors (TROVA) was designed and constructed at the Politecnico di Milano. In the facility, expansion flows of different organic compounds in non-ideal conditions in the close proximity of the liquid-vapor saturation curve can be investigated by independent measurements of pressure, temperature and velocity.

To investigate experimentally the non-ideal compressible-fluid flows of organic compounds in typical operating conditions for ORC applications, the Test Rig for Organic Vapors (TROVA) was designed and constructed at the Politecnico di Milano. In the facility, expansion flows of different organic compounds in non-ideal conditions in the close proximity of the liquid-vapor saturation curve can be investigated by independent measurements of pressure, temperature and velocity.

The facility implements an ORC (either sub-critical or super-critical), where the expansion process take place within a nozzle replacing the turbine. A straight axis converging-diverging nozzle was chosen, being it the simplest geometry providing an expansion from subsonic to supersonic flow in the operating conditions of interest. The size of the nozzle is large enough to guarantee that within the expanding flow a large isentropic core is preserved, thus making it possible to measure temperature and pressure fields without the use of calibrated probes.

Total pressure and temperature are measured in the settling chamber ahead of the nozzle inlet; static pressure taps at different sections along the nozzle axis are used to follow the flow evolution as it expands from rest to supersonic conditions. In order to reduce the required input thermal power, a batch operating facility has been selected.

Total pressure and temperature are measured in the settling chamber ahead of the nozzle inlet; static pressure taps at different sections along the nozzle axis are used to follow the flow evolution as it expands from rest to supersonic conditions. In order to reduce the required input thermal power, a batch operating facility has been selected.Schlieren optical bench

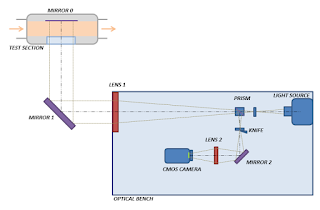

A double pass-type parallel light Schlieren system with the emitting and receiving optical components mounted on an optical table was used. This configuration is shorter and easier to align with respect to the classical Z-type system. A schematic sketch of the system is shown in figure. A 100 W Hg arc-lamp is used as the light source. The light from the lamp is focused by a F/1.5 silica lens into a circular spot of about 3 mm in diameter and then collimated to form parallel light rays by a Schlieren lens head (Lens 1). The latter has a diameter of 150~mm and a focal length of 1000

A double pass-type parallel light Schlieren system with the emitting and receiving optical components mounted on an optical table was used. This configuration is shorter and easier to align with respect to the classical Z-type system. A schematic sketch of the system is shown in figure. A 100 W Hg arc-lamp is used as the light source. The light from the lamp is focused by a F/1.5 silica lens into a circular spot of about 3 mm in diameter and then collimated to form parallel light rays by a Schlieren lens head (Lens 1). The latter has a diameter of 150~mm and a focal length of 1000 mm. The collimated light beam is deflected by a circular mirror (Mirror 1) before traversing the test section. It is then reflected back to the Schlieren head by the metallic mirror 0 (namely, by the polished nozzle back wall) and focused on the vertically aligned knife edge. The knife orientation allows to visualize the density gradient along the nozzle axis. A cubic beamsplitter (prism) separate the light beam originated by the light source and the reflected one. A lens of 160 mm focal lenght and 50 mm diameter is located behind the knife (Lens 2 ) and forms a real image of the test section on the sensor of a high speed CMOS camera. To allow a suitable long recording time the CMOS camera resolution and frame rate were respectively set to 1024 x 512 pixels and to 100 fps (frames per second), while the exposure time was set to 20μs.

No comments:

Post a Comment